Forming

*Click Button For Details*

Roll

At CQM, we specialize in roll forming, an efficient and cost-effective metal forming process involving the continuous bending of a long strip of metal into a desired cross-sectional profile. This method is widely used in industries like automotive, construction, and appliance manufacturing.

Roll forming allows us to produce complex shapes with consistent dimensions and tight tolerances. Using multiple sets of precisely positioned rollers, we gradually bend the metal strip to create intricate profiles, making it ideal for applications requiring consistent quality and high-volume production.

The process enables the production of long lengths of metal components, reducing the need for additional joining or welding. This saves time and enhances the overall strength and durability of the final product.

Roll forming is versatile, accommodating a range of metals including graded steel, and aluminum, suitable for various applications.

By leveraging our roll forming expertise, we can efficiently produce the precise components your products require, ensuring they meet quality standards.

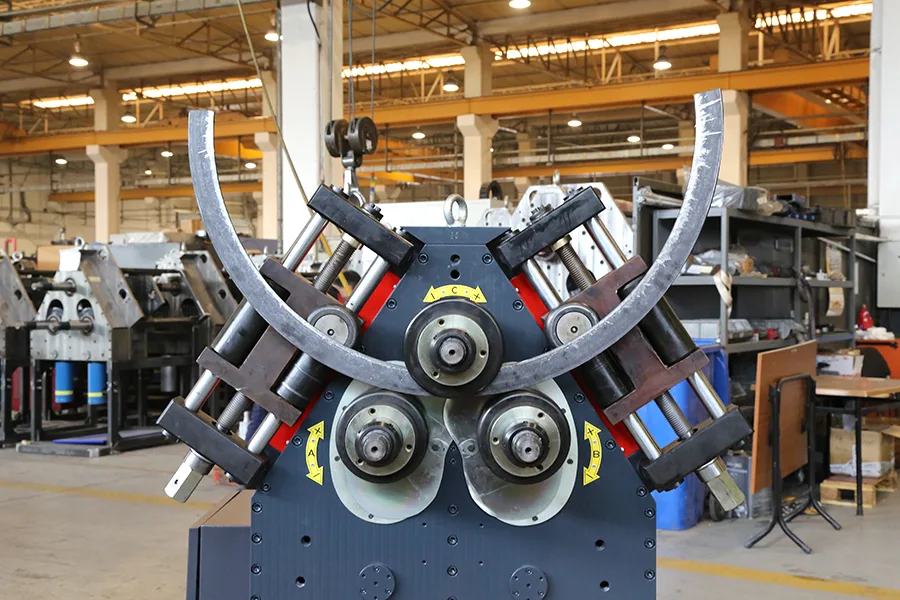

Bending

At CQM, we offer comprehensive bending and forming services, essential processes that create complex shapes and structures from various materials. Our capabilities include press brake bending, tube bending, and custom forming.

Our team of skilled professionals uses advanced equipment like CNC-controlled machines and innovative techniques to ensure accurate and consistent results in bending and forming.

One advantage of our services is the ability to create custom shapes and designs. We can bend and form materials into unique and intricate shapes, meeting specific client requirements. This flexibility allows for numerous possibilities in product design and functionality across industries such as automotive, construction, and manufacturing.

We prioritize quality and efficiency, understanding the importance of delivering projects on time and within budget. Our processes are optimized for fast turnaround without compromising precision, and we adhere to strict quality control standards.

By leveraging our bending and forming expertise, we can efficiently produce the precise fabrication solutions your products require, ensuring they meet your specific design and functionality requirements.

Angle

At CQM, we specialize in angle forming, involving the precise bending or shaping of metal to create specific angles and profiles. Angle forming is versatile, allowing us to create angles of different degrees and sizes for a wide range of products, such as structural components, brackets, frames, and supports.

Our team uses advanced equipment like CNC press brakes and angle rollers to ensure precise and accurate results. We work with various materials, including graded steel, and aluminum, catering to different industry needs.

We aim to meet client specifications and deliver quality in every project. Our capabilities allow for the creation of custom angles and complex shapes, providing solutions tailored to your design requirements.

By leveraging our angle forming expertise, we can efficiently produce the precise angles your products require, ensuring they meet quality standards.

CQM: Custom Quality Manufacturing

Request Quote

- [email protected]

- 519-765-1339

-

516 John St N #8, Aylmer,

ON N5H 3H3, Canada

- [email protected]

- 519-765-1339

- 516 John St N #8, Aylmer, ON N5H 3H3, Canada